Production process

Our production hub covers over 8,000 m².

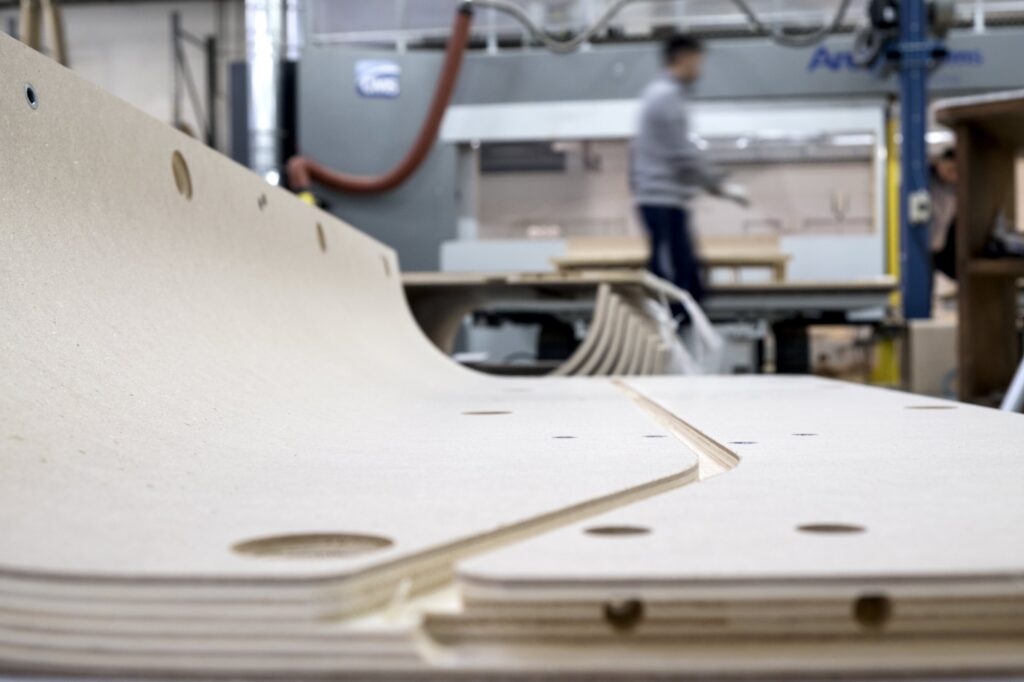

This is where the stages of creating curved elements take place, from cutting the raw material to packing the finished and possibly painted product.

Partnership and collaboration with reliable suppliers allow us to guarantee you a flexible and complete service.

Our departments, our know-how

Warehouse, Sizing, Plate Press, Membrane Press, Curved Presses, Mechanical Processing with 5-axis and 3-axis machining centres, Special Processing, Sanding and Packing.

Warehouse:

rich assortment of raw materials, including FSC PEFC and CARB ATCM PHASE 2 U.S.EPA TSCA title VI, and storage of about a thousand molds and equipment, some of which are for the exclusive use of our customers.

Sizing:

equipped with automatic loading angular panel saw.

The plane press and the membrane press:

Flat pressing, to ensure control over our gluing mixes, and the membrane press for wood postforming, PVC, or plastics also thanks to our partner

Curving process presses:

- 20 presses with capacity for pressing elements with non-standard dimensions up to 3500×1500.

- High-frequency technology with wooden moulds.

- Electric or oil heating and cooling technology with aluminium moulds.

Mechanical processing:

3 and 5-axis machining centres for very high precision in all cutting, milling and drilling operations

Special processing:

Such as edging and assembly

Sanding and packing:

Manual and semi-automatic sanding, researched for the individual product to obtain excellent attention to detail, and packaging customised according to the customer’s specific needs, guaranteeing the safety of the material during delivery